Industrial system overhaul and maintenance service is the value-added service provided by Topchi for the difficulties faced by customers, which can effectively solve the urgent problems faced by customers, such as urgent, professional, scattered, high comprehensive technical requirements, potential safety hazards, large cost and so on. The maintenance of industrial system is different from the maintenance of conventional single product. It covers a wide range of industries, has great technical difficulties and is highly professional. It is not only necessary to consider the operating conditions of single equipment, but also the optimization of the whole system. It is necessary to go deep into the process conditions to fundamentally provide an effective solution.

Torchi has R & D center of industrial system, product center (Manufacturing), evaporation crystallization, filtration separation, gas and other professional industrial system business departments. These industrial systems are not usually an independent main system, but also include various professional auxiliary systems. These systems also involve different main equipment, dynamic equipment, I & C and other equipment or accessories Multi professional cooperation can be completed, which is why torchi has the ability to solve comprehensive problems.

Torchi has its own construction and maintenance team, as well as pipeline installation certificate, safety and environmental protection, anti-corrosion and insulation certificate. After years of deep research in various professional fields of industrial system, torchi has the ability to extend the service chain from fault diagnosis, energy consumption optimization, maintenance, parts supply, etc., which effectively guarantees the professionalism of industrial system maintenance and repair.

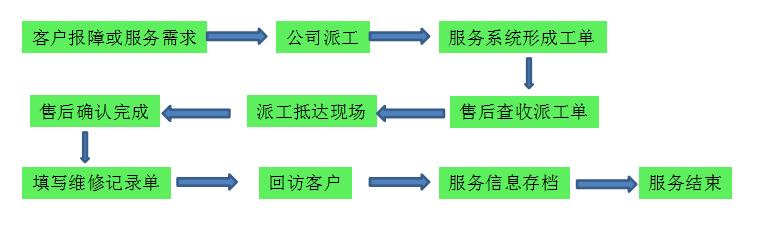

Torchi not only provides long-term repair and maintenance services for the industrial system produced by the company, but also assists customers to provide repair and maintenance services for some imported systems and systems supplied by other domestic suppliers, and provides some domestic technology breakthrough services. It is a rational choice to respond to the professional industry with professional skills! The work flow of industrial system maintenance and repair is as follows:

Main system fault diagnosis and transformation service: the main system mainly refers to the main evaporative crystallization device composed of the core system and its circuit. First, stop the main system in accordance with the safety operation procedures, eliminate the possible risks of maintenance and repair, analyze the problems fed back by customers, extract the technical data of the main system, check whether there are original design defects, and at the same time, conduct investigation and diagnosis of the site conditions, confirm the consistency of each link's operation and the original data, find out the core problems of the main system and provide solutions Resolution plan;

Auxiliary system fault diagnosis and transformation services: feed system, pre filtration system, heating system, condensation recovery system, vacuum pumping system, online cleaning system, waste gas treatment system and other professional subsystems. Firstly, the auxiliary system is associated with the system shutdown, and the hidden danger of maintenance is eliminated according to the operation procedures, the consistency between the operation of the auxiliary system and the original design data is reviewed, and the main cause of the problem is the problem caused by the main system or the auxiliary system itself is analyzed. The operation of each equipment, instrument and component on the auxiliary system is checked to confirm whether it is normal. Finally, the comprehensive analysis is made Cause and issue solution.

Spare parts supply and conventional material inventory: tuochi has been equipped with some spare parts for a long time to facilitate maintenance and replacement, such as evaporator scraper, gasket, bolt and nut, conventional flange pipe fittings, filter internals, etc., pumps, valves and some instruments also have a certain inventory, and at the same time, tuochi has its own complete supporting system, which can quickly respond to various needs of customers.

Resource recycling service: tuochi can provide some materials for reprocessing to achieve recycling to save costs. Tuochi can provide assessment, detection and regeneration, so that it can be recycled or extend its service life, and provide refined services for customers, such as filter core of filter, regeneration of activated carbon, repair of pump valve, etc., which can improve efficiency through optimization.

Troubleshooting of electronic control logic |

Valve maintenance |

Disassembly and maintenance of pump |

Adsorption and regeneration of activated carbon |

Upgrading and transformation of industrial system performance optimization: some industrial systems need to increase their output or improve one of their performance, and tuochi can provide professional services. According to the requirements of on-site project transformation, tuochi provides complete services from technology, manufacturing, installation to on-site commissioning.

Environmental protection and safety upgrading and Transformation: due to the change of site environment, some industrial systems need to improve the level of explosion-proof and other safety protection, or need to improve some indicators of environmental protection. Topchi can provide professional services:

Localization transformation and restorative maintenance: some imported industrial systems are difficult to provide timely services for the Chinese market due to the supplier's difficulties, so tuochi can use its own professional ability to assist in the repair or localization function transformation to help customers achieve better results.