Coalescers shall be used to remove solids and liquids from the gas. It is divided into two-stage structure. In the first stage, a filter element with the function of "filter coalescence" is used. First, solid impurities in the air flow are filtered and liquid drops are coalesced. The coalesced liquid drops are carried to the second stage container by gas, separated by the second stage mist catcher, and the separated liquid is stored in the liquid collection bag.

Principle of coalescer: when the gas enters into the remaker, the larger droplets and solid particles collide with each other in the pipeline, and the impact will generate centrifugal force, which makes these larger solid-liquid impurities settle to the bottom of the container, while the finer suspension droplets enter the second filter, and the dry and clean gas is discharged from the container.

Type of coalescence and separation: gravity, collision, centrifugation, filter

Summary of engineering examples of hydrogen peroxide coalescer

Application case

Hydrogen peroxide degreasing coalescer in Shuangyang, Huaihua, Hunan Province in early October 2017

High tech is put into use, and the actual use is summarized as follows:

Shuangyang high tech adopts TBU three solvent system of Liming Chemical Design Institute for high efficiency fixation

Since the completion of the second phase technical transformation in 2016, the product has slightly turbid, which directly affects the product sales. After using hydrogen peroxide degreasing coalescer in October 2017, the product quality was significantly improved, the color was transparent, and the TOC decreased from 176ppm to 102ppm.

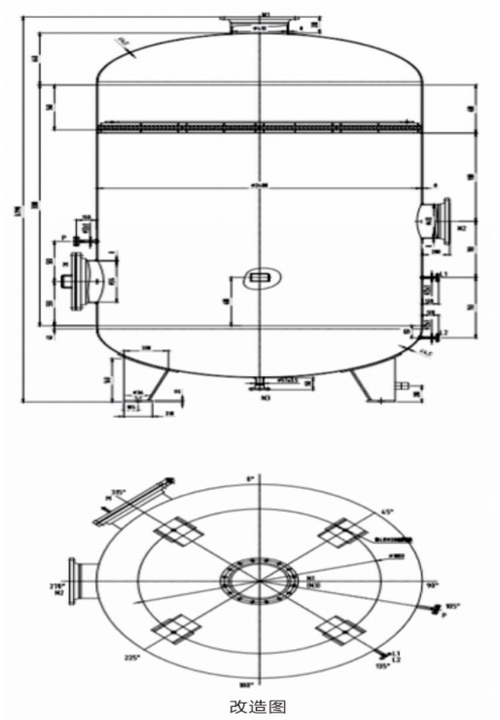

Jiangsu torchi advanced separation technology is 100000 tons / hppo to produce propylene oxide ∨ 1202c coalescer transformation

100000 t / a hppo to propylene oxide project of Changling branch of Sinopec

The total non methane hydrocarbon content at the outlet of coalescer separator is less than 1.5g/m³ at 40000 Nm3 / h and 5 ℃