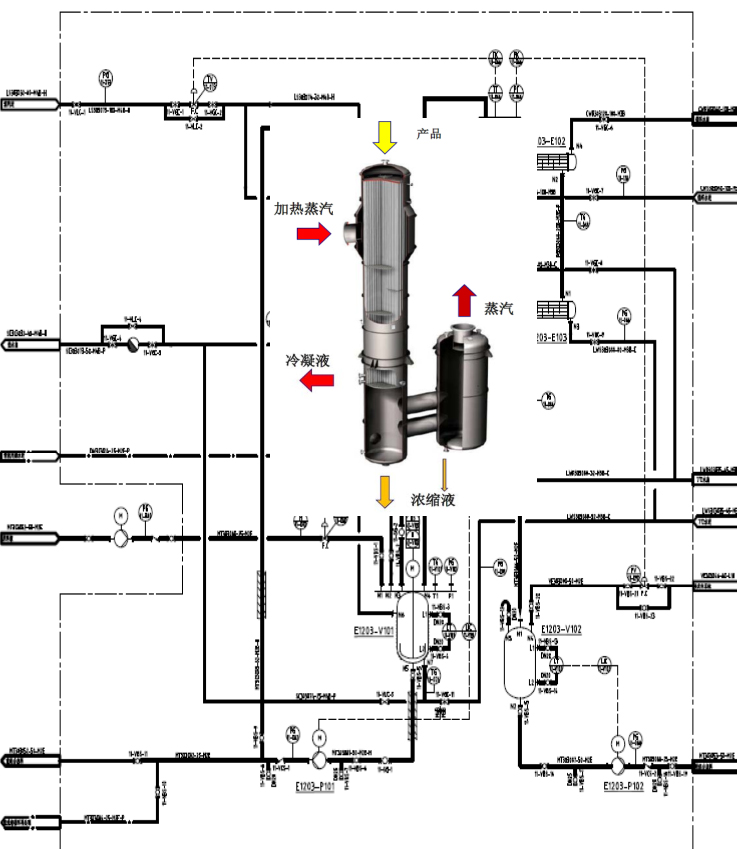

● the evaporation system consists of falling film evaporator, vacuum system, condensation system and other supporting facilities;

● the feed liquid is added from the top of the evaporator and falls into a film shape along the pipe wall under the action of gravity, and in the process of evaporation and concentration, the concentrated liquid is obtained at the bottom of the equipment. It is suitable for materials with high evaporation concentration and viscosity in the range of 0 0A 0.05-0.45pa. S, and materials with a small amount of suspended solids.

● film flow, high heat transfer coefficient.

● small operating temperature difference, especially suitable for energy-saving multi effect and MVR evaporation process.

● the material has short residence time, good control, and can be started and stopped quickly.

● It is suitable for evaporation of heat sensitive materials due to its low temperature operation in vacuum and short residence time.

● The evaporation of the membrane in the material heating tube is carried out by the pump. Most of the concentrated liquid is pumped at the bottom of the evaporator, and the smaller part of the concentrated liquid is forced to separate with the two steam inlet water separator. The material is not seriously affected, and the foam formation can be avoided effectively. Therefore, the falling film evaporator is suitable for evaporating and concentrating the foaming material.