|

|

| Automatic backwash filter | Automatic backwash filter |

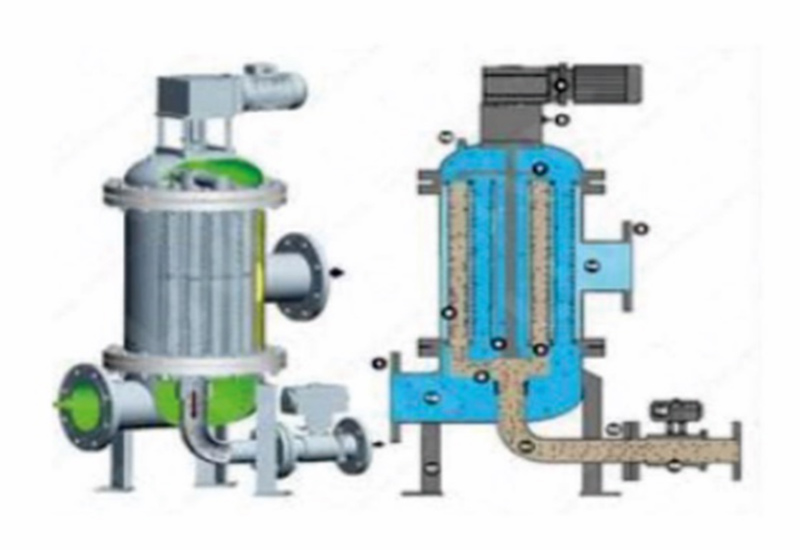

Automatic backwash filter is a kind of industrial automatic filter which can provide a variety of comprehensive purposes. It can automatically clean, filter and drain. During backwashing, the flow is continuous, and the cleaning and filtering period can be adjusted.

The equipment directly intercepts the impurities in the liquid, removes the suspended matters and particles, reduces the turbidity, purifies the medium, reduces the generation of system dirt, bacteria and algae, rust, etc., so as to purify the water quality and protect the normal operation of other equipment in the system. Due to the intelligent (PLC, PAC) design, the system can automatically identify the degree of impurity deposition and automatically drain the sewage valve signal. </p>

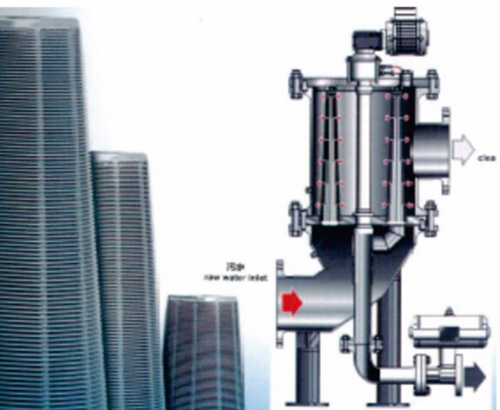

The automatic backwash filter overcomes many shortcomings of traditional filter products, such as small amount of pollutants, easy to be blocked by pollutants, the filter part needs to be disassembled and cleaned, and the filter status cannot be monitored. It has the function of filtering raw water and automatically cleaning and draining the filter element. When cleaning and draining, the system continuously provides water, which can monitor the working status and automation degree of the filter Very high. It covers the requirements of filtering accuracy from 20um to 3000um.

Industrial water - pretreatment, sea water desalination - prefiltration, system water - prefiltration; food and pharmaceutical light chemical industrial wastewater, circulating water filtration, emulsion regeneration, waste oil, liquid raw materials, etc.

The sewage to be filtered enters the shell from the lower part of the filter, enters the inner cavity of the filter element from the bottom to the top through the flower tray, and then flows out through the filter element. The purified water obtained after filtration flows out from the water outlet on the upper part of the filter, and the solid impurities are trapped in the inner side of the filter element. When backwashing is carried out, the water inflow does not need to be cut off. The motor drives the suction cup of the filter element to rotate, and at the same time, opens the backwash blowdown valve to backwash each filter element through the filtered purified water in turn.

The pressure difference between the water pressure and the atmospheric pressure in the filter results in the reverse flow of the filtrate, which can remove the impurities trapped on the inner wall of the filter element. After the suction cup rotates for 1 week, the recoil ends. Then the recoil valve closes and the drive motor stops.