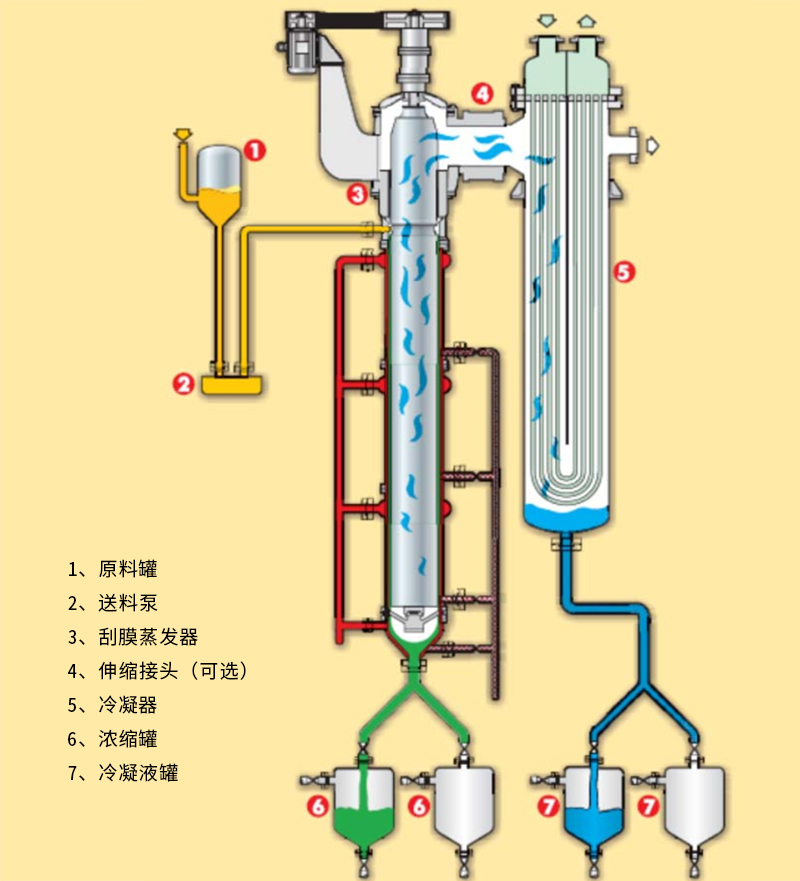

● evaporation system is composed of film scraping evaporator, vacuum system, condensation system and other supporting facilities;

● the film evaporator has a heated cylinder, which is equipped with a rotor scraper. Through the high-speed rotation of the rotor, the material forms a film along the inner wall of the cylinder to form the film evaporation advantage, that is, the gas-liquid interface temperature difference is small and there is no static pressure difference. Compared with falling film evaporator, the total heat transfer coefficient is as high as 7000kj / ㎡.

● due to high evaporation rate and short residence time of materials, it can effectively prevent materials from deteriorating.

● the rotation of scraper makes the material form film along the inner cylinder wall, and the main body in the flow field area of the equipment is gas. Under the action of vacuum pump, the material flows out of the cylinder rapidly, effectively reducing the resistance drop of the equipment, so that the design of the length diameter ratio of the equipment is not affected by the resistance drop.

In most cases, the minimum vacuum degree of the evaporation system can reach P = 0.1MPa under the condition of vacuum and low temperature; low temperature operation can effectively avoid the decomposition, polymerization and deterioration of heat sensitive materials.

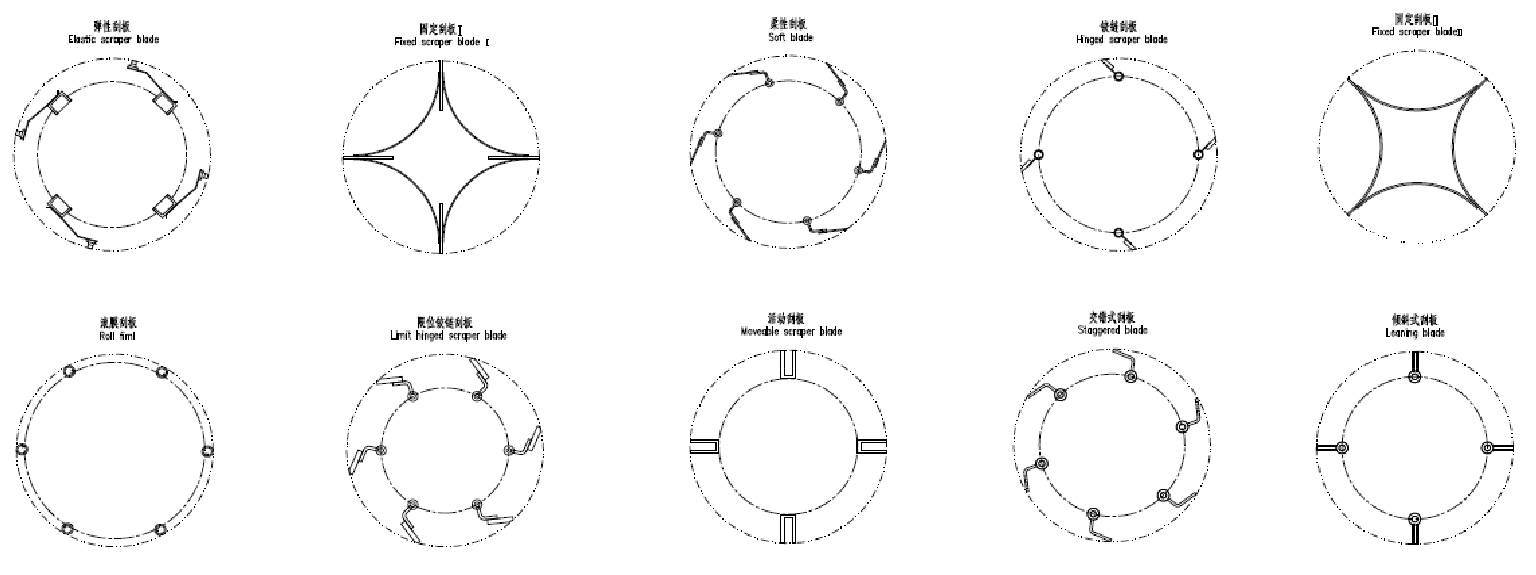

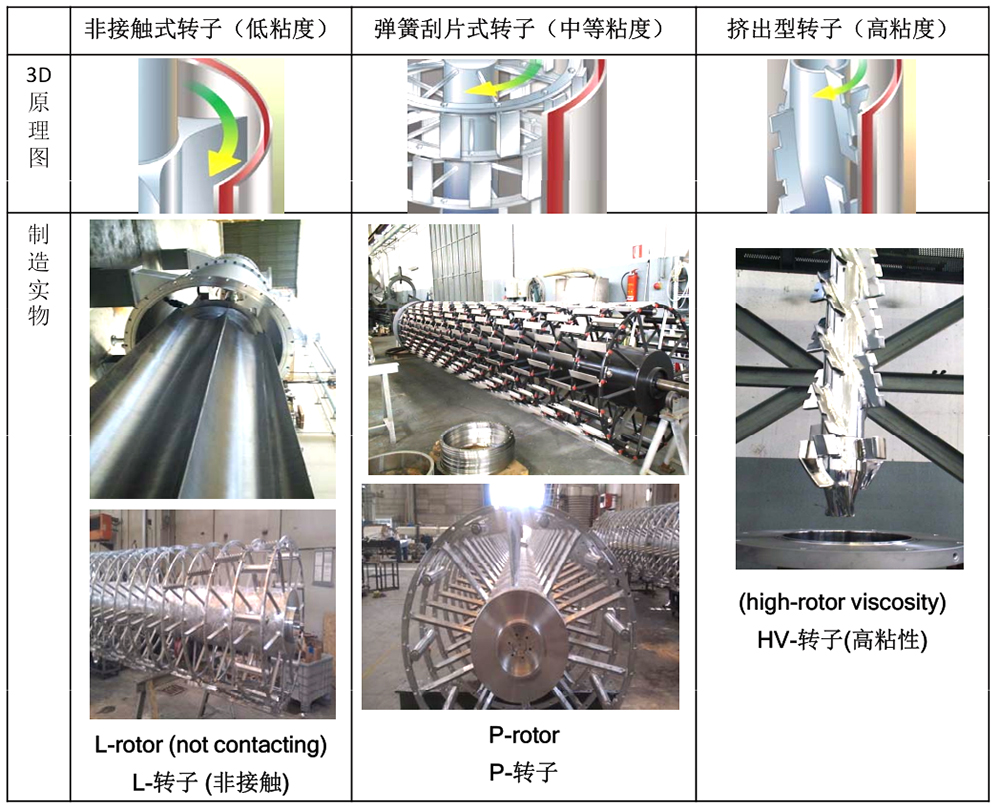

● different rotor structures and configurations can be optimized according to specific requirements, and customized design can be carried out according to the viscosity particle residue of liquid medium.

● compared with falling film evaporator, it is more able to use low-grade steam for efficient evaporation under the operation condition of low temperature and vacuum. Therefore, it can be designed as a single task or multi-functional operation, which is suitable for the end effect evaporator of multi effect evaporation, or combined with MVR technology.

-It can be used for heating area of 0.15-40 square meters

-Contactless rotor for low viscosity products

-Contact rotor with blade for medium viscosity

-Extruder for high viscosity materials, push materials

-Contact material: 304 / 316L, duplex steel SAF2205, alloy material HC series, titanium material or glass lining material